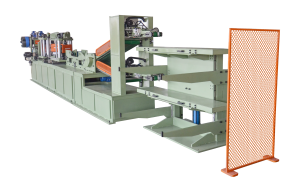

Laini iṣelọpọ rirẹ transformer gba ọpọlọpọ awọn eto AC servo. Ni atele lo ninu: ikanni gbigbe ohun elo nipasẹ servo motor lati ṣeto iwọn ohun elo ni iṣẹ iboju ati ipo adaṣe. Shearing ati v-notching gba AC servo motor bi agbara awakọ, pẹlu iyara esi iyara, ariwo kekere, gbigbọn kekere, itọju irọrun.

Awọn ẹya ara ẹrọ

Decoiler iyara igbohunsafẹfẹ, eto ipasẹ aifọwọyi.

Iṣakoso itanna ikojọpọ ilọpo meji, Rirọpo ipo irọrun.

Ko si ọfin iwulo fun Ẹrọ Ibi ipamọ Ohun elo, Rii daju ailewu ati irọrun.

Iṣakoso PLC, Servo ṣatunṣe iwọn, kikọ sii Servo

V notching, Iho punching, Irẹrun ẹrọ iru collocation, pade gbogbo iru aini

Depiler laifọwọyi, tolera daradara

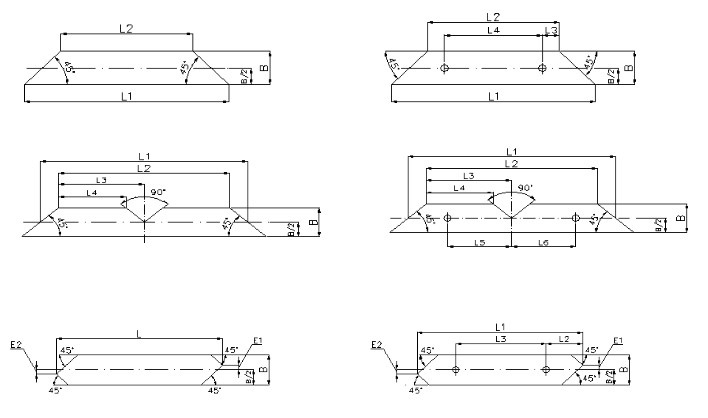

Mojuto iru nipa transformer mojuto lamination ẹrọ

Irẹrun meji kan Punch

Irẹrun meji Punch

Irẹrun Meji-Punch Central Positioning Igbesẹ

Imọ paramita

| Amunawa mojuto Ige Machine | ||||

| Awoṣe ẹrọ | HJ-300 | HJ-400 | HJ-600 | |

| Iwọn ilana | Gigun dì (mm) | 400–1800 | 400-2200 | 400-3500 |

| Ìbú dì (mm) | 40–300 | 50–400 | 60–600 | |

| Sisanra ti dì (mm) | 0.23–0.35 | |||

| Ilana ilana | Ifarada ti ipari (mm) | ≤±0.15 | ||

| Igun irẹrun | ±0.025º | |||

| Irẹrun Burr (mm) | ≤0.02 | |||

| Ekun sipesifikesonu | Ifarada ti iwọn (mm) | ≤±0.1 | ||

| Burr (mm) | ≤0.03 | |||

| Ifarada ti S (mm/2m) | ≤0.2 | |||

| Iyara ifunni (m/min) | 0–180 | 0–200 | 0–200 | |

| Rirẹ ṣiṣe | Iwọn 160mm, Pẹlu ajaga v-notch L1 gigun 800 mm, Ẹsẹ ẹgbẹ L1 gigun 600 mm, Apapo Shear, diẹ sii ju tabi dogba awọn akoko 36 fun iṣẹju kan | Iwọn 200mm, Pẹlu ajaga v-notch L1 gigun 1000 mm, ipari ẹgbẹ L1 ipari 800 mm, Apapo Shear, diẹ sii ju tabi dogba si awọn akoko 30 fun iṣẹju kan. | Iwọn 200mm, Pẹlu ajaga v-notch L1 gigun 1000 mm, ipari ẹgbẹ L1 gigun 800 mm, Apapo Shear, diẹ sii ju tabi dogba si awọn akoko 36 fun iṣẹju kan. | |

| De-coiler | Opoiye | Ori meji | ||

| Max.loading/ori ẹyọkan (kg) | 1500 | 1800 | 2000 | |

| Coil akojọpọ dia mm | Φ500 | |||

| Max okun lode dia mm | Φ1000 | |||

| Docoiler iyara m / min | 0-180 adijositabulu | |||

| Npọ ibiti o mm | Φ480–Φ520 | Φ480–Φ520 | Φ480–Φ520 | |

| Ẹrọ ifipamọ | maṣe yọọda | |||

| Fọọmu ifunni | Nikan servo ono | Nikan servo ono | Double servo ono | |

| V-notching | Eto akiyesi (mm) | ± 25 | ± 25 | ± 35 |

| Igbesẹ | 7 igbesẹ | |||

| Punching ẹrọ | laisi | 1 ẹyọkan | 1 ẹyọkan | |

| Ẹrọ irẹrun | 2 kuro (45º&135º kọọkan ni ẹyọ kan) | |||

| Depilatory | Devid ohun elo si oke ati isalẹ, stacking | |||

| Lapapọ Powerkw | 25 | 30 | 45 | |

| Ibi ti ina elekitiriki ti nwa | 380V± 10% 50Hz (Tabi adani) | |||

Kini Trihope?

Ile Amunawa Kilasi 5A pẹlu ojutu kikun fun Ile-iṣẹ Amunawa

1, Olupese gidi kan pẹlu awọn ohun elo inu ile pipe

2, Ile-iṣẹ R&D ọjọgbọn kan, nini ifowosowopo pẹlu Ile-ẹkọ giga Shandong ti o mọ daradara

3, Ile-iṣẹ iṣẹ ti o ga julọ ti o ni iwe-ẹri pẹlu Awọn ajohunše Kariaye bii ISO, CE, SGS ati BV ati bẹbẹ lọ

4, Olupese iye owo to dara julọ, gbogbo awọn paati bọtini jẹ awọn burandi kariaye bi Simens, Schneider ati Mitsubishi ati be be lo.

5, Alabaṣepọ iṣowo ti o gbẹkẹle, ṣiṣẹ fun ABB, TBEA, PEL, ALFANAR, ZETRAK ati be be lo ni awọn ọdun 17 ti o ti kọja

Q3: Bawo ni lati funni ni didara naa?

Didara naa jẹ itẹwọgba nipasẹ ijẹrisi orilẹ-ede, ọpọlọpọ awọn oṣiṣẹ ayewo agba, olupese ohun elo iyasọtọ rii daju aabo ati igbẹkẹle ohun gbogbo lati ibi ipamọ lati pari awọn ẹru naa.

Q4: Ṣe o pese fifi sori okeokun ati ikẹkọ?

A: O jẹ iyan .Ile-iṣẹ wa yoo pese itọnisọna ati awọn fidio fun fifi sori ẹrọ ati fifunni.

Ti o ba nilo, a le firanṣẹ awọn onimọ-ẹrọ fun fifi sori okeokun ati ikẹkọ.

Q5: Bawo ni atilẹyin ọja gun to?

A: Akoko atilẹyin ọja jẹ awọn oṣu 12. Lakoko awọn iṣoro eyikeyi, ile-iṣẹ wa yoo dahun laarin awọn wakati 24.