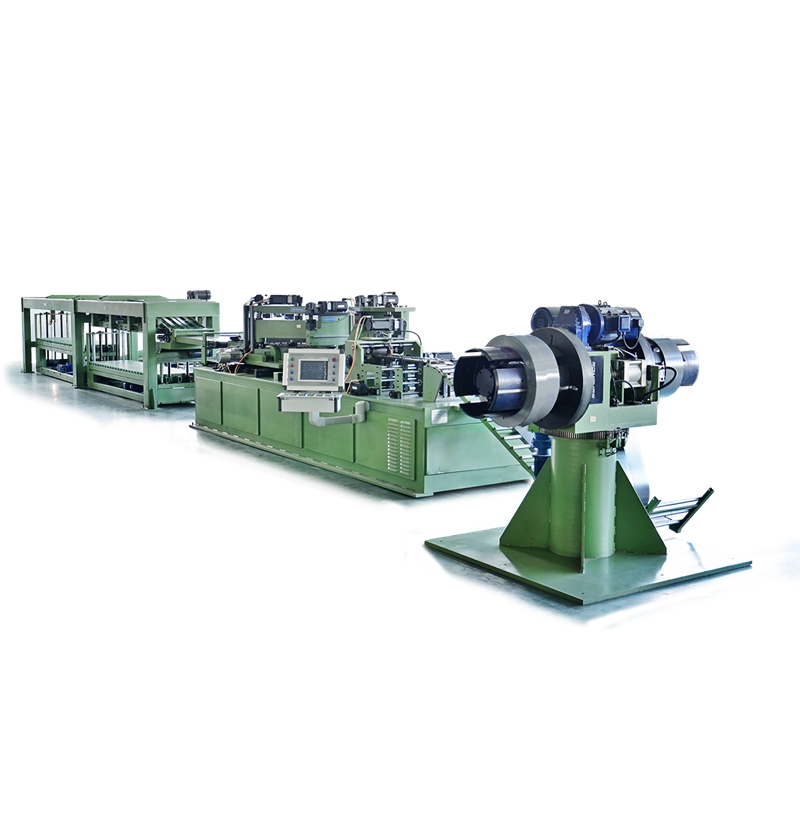

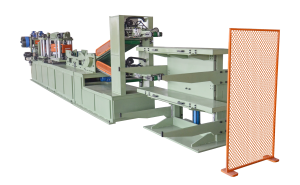

Reactor Disk Core Cutting Line

Composition of equipment

What is Trihope?

5A Class Transformer Home with a full solution for the Transformer Industry

1, A real manufacturer with complete in-house facilities

2, A professional R&D Center, having collaboration with well-know Shandong University

3, A top performance company certificated with International Standards like ISO, CE, SGS and BV etc

4, A better cost-efficient supplier , all key components are international brands like Simens, Schneider and Mitsubishi etc.

5, A reliable business partner, served for ABB, TBEA, PEL, ALFANAR, ZETRAK etc

Q3: How to grantee the quality ?

The quality is approved by national certificate ,several senior inspection personnel ,the brand material supplier ensure the safety and reliability of everything from storage to finished the goods .

Q4:Do you provide overseas installation and training ?

A: It’s optional .Our company will provide the guidance and videos for installation and commissioning.

If you need ,we can send engineers for for overseas installation and training.

Q5:How long is the warranty ?

A:The warranty period is 12 months .During Any problems ,our company will respond within 24 hours .

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com