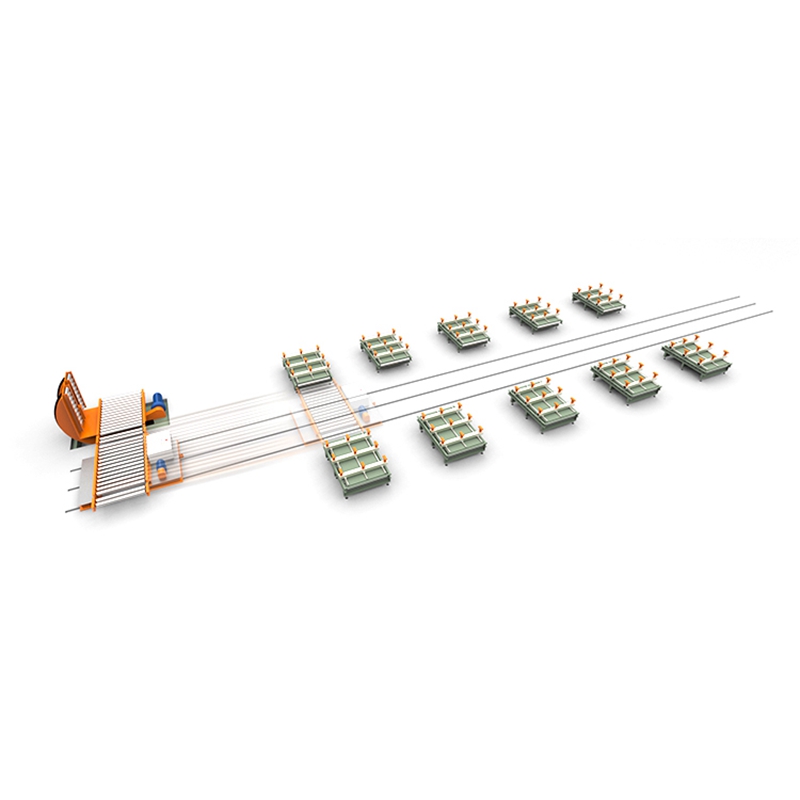

The Key Components of Core Stacking Line include Core tilting table, Automatic Trolley, Moveable Core Stacking Table and Roller Table

Core Tilting Table

Effective loading: Core weight ≤ 4 Ton

Workpiece Shape: Core Max Dimension ≤ W 2200, H 2400, T 400mm

Tilting Speed: 0-90°:≤ 60 s

Tilting mode: Electric

Roller drive: Motility

Automatic Trolley

Trolley Load : 5 ton

Walking speed: 20m/ min

Roller drive speed: 8m/min

Roller drive qty: 1

Overall dimension : L 2500* W 2000 *H 400mm(ground to roller)

Power supply : AC 24V, 3KW

Control mode: PLC Control, It can be automatically positioned between stacking station and tilting station

Safety protection: The front and behind of trolley have walking protection, induction distance is not less than 0.3 meters, there is an emergency stop switch at front and behind.

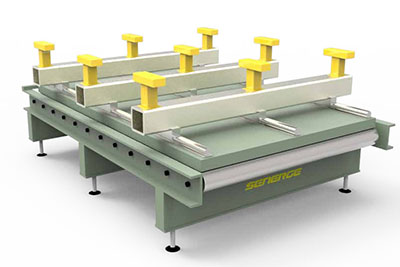

Moveable Core Stacking Table

Effective Loading: ≤ 4 ton

Overall Dimension: 1600* 1200 (1800) *400mm (When the shrink rod is extended 1800)

Core column adjust range : A-B, B-C (Mo) : 150- 710mm

Core Height: Max 1600mm

Core Stack Height: ≤ 400mm

Core Roller Table

Roller power: self-power

Effective load: ≤ 4 tons

Single roller load ≤ 300kg

Overall dimension :1610 * 1120 * 400mm (ground to roller top ±20mm)

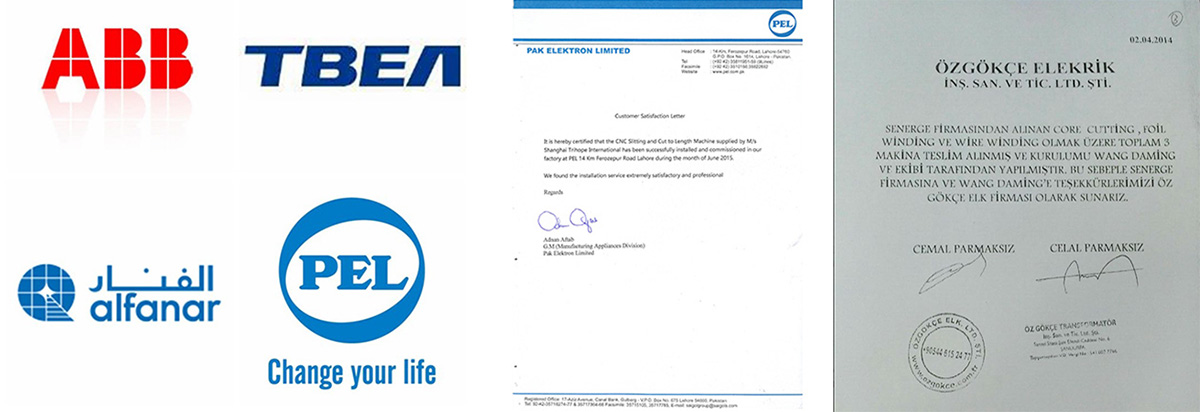

What is Trihope?

5A Class Transformer Home with a full solution for Transformer Industry

1A, a real manufacturer with complete in-house facilities

2A, a professional R&D Center, having collaboration with well-know Shandong University

3A, a Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

4A, a better cost-efficient and convenient supplier equipped with international brand components like Simens, Schneider, etc

5A, a reliable business partner, served for ABB, TBEA, PEL, ALFANAR, etc in the past decades

Q1: Is this Core stacking line can be customized each part?

A: Yes, we could make the design according to your requirements like stacking table working station, Trolley travel way, stacking table size. We have a powerful design department which could recommend the best solution to you.

Q2: Can you provide the turn-key service of supplying complete machinery and equipment for a new transformer factory?

A: Yes, we have rich experience for establish a new transformer factory. And had successfully helped Pakistan and Bangladesh customers to build a transformer factory.

Q3: Can u provide the After-sales installation and commissioning service in our site?

Yes, we have the professional team for after-sales service. We will provide installation manual and video when machine delivery, If you need, we can also delegated engineers to visit your site for installation and commission. We promise we will provide 24 hours of online feedback when you need any help.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com