I. Summary

LV foil coil uses different thickness copper or aluminum foil as conductor, wide band type insulation material as layer insulation, complete winding in foil type winding machine, forming roll coil.

This equipment can also be applied to the similar coil winding of electrical industry.

The machine adopts PLC control method with the characteristics of high degree of automation.

Ⅱ. Composition and Function of the Equipment

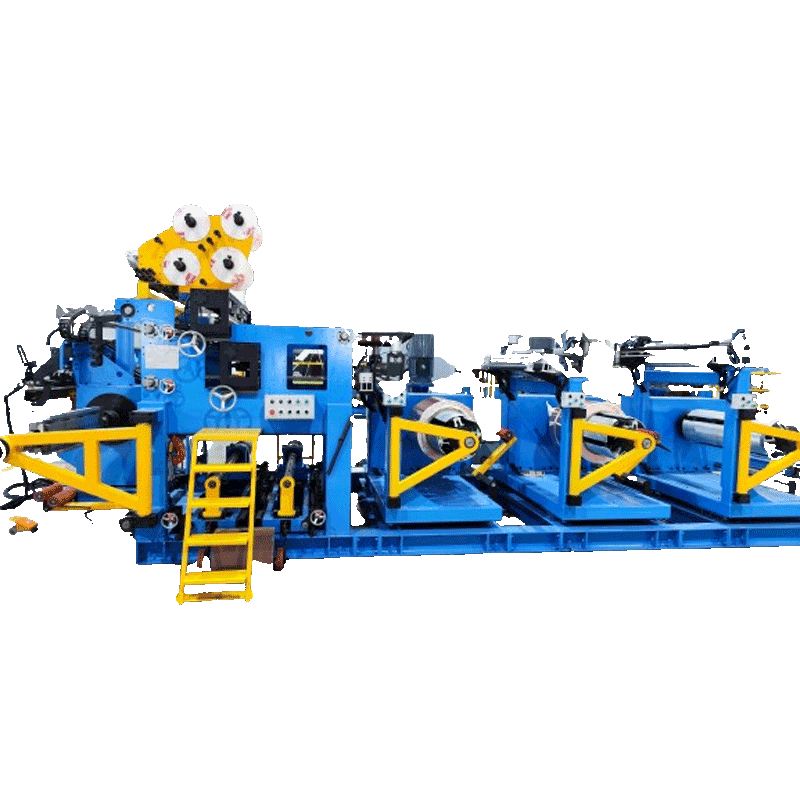

BR/III-1100 Three-Layer Foil Winding Machine include

1) Foil de-coiling device 2) Winding device 3) Layer insulation decoiling device

4) The main frame parts 5) Welding device 6) Deburring and cleaning device

7) Cutting device 8) The end insulation uncoiling device etc

III. Main Technical Parameters

|

Sr# |

ITEM |

SPECIFICATION |

|

1 |

Coil |

Processing range |

| 1.1 | Axial length |

250~1100 mm |

|

1.2 |

Axial length(Include lead) | 400~1760 mm(with lead RH 16 inch, LH 10inch) |

|

1.3 |

Outer diameter (Max) |

Φ1000 |

|

1.4 |

Coil form | Round/cylindrical/rectangular/coil weight ≤2000KG |

|

1.5 |

Center height |

850mm |

|

2 |

Coil Material |

Copper foil, aluminum foil |

|

2.1 |

Width |

250—1100 mm |

|

2.2 |

Thickness (Max) (Total thickness) |

Copper foil:0.3~2.5mm Aluminum foil: 0.4~3mm |

|

2.3 |

Coil inner diameter |

Φ400-500mm |

|

2.4 |

Coil outer diameter (Max) |

φ1000mm |

|

De-coiler |

Independent three sets |

|

3.1 |

Length of bearing cylinder |

1150 mm |

|

3.2 |

Expansion range of bearing cylinder |

Φ380~φ520 |

|

3.3 |

Bearing capacity (Max) |

2000KG |

|

3.4 |

Expansion force (Electric) |

0~15000N Expansion force stepless adjustable |

|

3.5 |

Mode of offset correction |

Manual/Automatic |

|

Winding machine |

|

|

4.1 |

Winding speed |

0~20 rpm |

|

4.2 |

Working torque (Max) |

≥ 8000 N•M |

|

4.3 |

Winding power |

20-30 KW |

|

4.4 |

Speed control way |

Frequency conversion stepless speed regulation |

|

4.5 |

Winding shaft |

50*90mm |

|

5 |

Welding device |

|

|

5.1 |

Welding mode |

TIG |

|

5.2 |

Conducting bar welding thickness |

≤ 20mm |

|

5.3 |

Welding speed | Auto-speed control 0~1m /min Stepless speed regulation |

|

6 |

Cutting device |

|

|

6.1 |

Cutting form |

Lead Screw Cutting Disc |

|

6.2 |

Cutting speed |

1.5 m / min |

|

6.3 |

Cutting length |

1150mm |

| 7. | Layer insulating de-coil device | |

| 7.1 | Layer insulation installed shaft |

2 sets |

| 7.2 | Layer insulation roll outer diameter |

≤φ400 mm |

| 7.3 | Layer insulation roll inner diameter |

φ76 mm |

| 7.4 | Layer insulation roll width |

250~1150 mm |

| 7.5 | De-coil shaft tension method |

Pneumatic type |

| 8. | The end insulation uncoiling device |

|

| 8.1 | Quantity |

Left and right each 4 sets |

| 8.2 | The end insulation outside diameter |

≤φ350 mm |

| 8.3 | The end insulation ininer diameter |

Φ56 mm |

| 8.4 | The end insulation width |

10-100mm |

| 9. | Rectifying device (foil alignment) |

Independent 3 sets |

| 9.1 | Rectifying mode |

Photoelectric system |

| 9.2 | Rectifying precision |

Random±0 .4 mm 20 layers coil ±1mm |

| 10. | Electric control system |

PLC automatic control mode |

| 10.1 | Number of digitals |

4-digital(0–9999.9)Counting accuracy 0.1 turn |

| 10.2 | Operation interface |

Color touch screen |

| 11. | Other |

|

| 11.1 | Layer insulation cutting device |

Configuration two sets |

| 11.2 | Foil material edges deburring device |

Configuration three sets |

| 11.3 | Foil material cleaning device |

Configuration three sets |

| 11.4 | Welding cooling water tank |

configuration |

| 11.5 | Power Supply | 3-PH, 380V/50HZ (Can be customrized) |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com