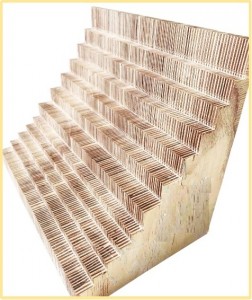

The Main Features of Insulation wood wooden-step milling machine:

(1) Full NUMERICAL control structure is adopted, with high machining accuracy and repeatability is ±0.1mm.

(2) Changed the original ordinary milling machine by the cutter limit defects, processing efficiency greatly improved, at least 3 times more than the ordinary milling machine processing efficiency.

(3) The operation is simple and reliable, and only the corresponding drawing input processing coordinates can be.The whole processing process is completed automatically without manual intervention, reducing the dependence on the operator’s business level.

(4) Adopt professional woodworking blade imported from Italy, with long service life, smooth processing surface and no damage to the pad.There’s no carbonation.

(5) The processing surface is smooth and beautiful, and can be used without polishing.

(6) Light and energy-saving, the total power of the system does not exceed 7.5KW.More than 50% energy saving than ordinary milling machine.

(7) Without foundation, it can be placed in any position in the insulation workshop.

Main technical parameters:

Saw blade blade speed: 2800rpm

Feed speed: 0~5m/min stepless speed regulation

Machining accuracy: ±0.2mm

Total power of the system: 7KW

Maximum pad size: 500 width *500 height *600 length (non-standard design as required)

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com