Product details:

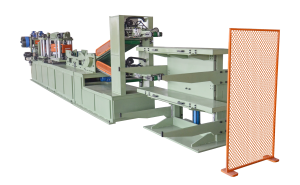

Main Character of spacer punching machine

Programming system is convenient and easy to understand

Intuitive man-machine interface programming, easier to use

Built-in block processing libraries, facilitate quick call

Real-time monitoring system

Block processing program can be stored in the memory controller

adopts four high-speed motorized spindle as milling head, machine design compact, short working table stroke leads to high speed machining efficiency.

Spacer milling machine adopts enclosed design, peripherals transparent type shield, internal sound-absorbing material, vacuuming mouth connected to external dust catcher.The inlet and outlet is designed for dust prevention, which can effectively control the overflow of dust and noise during the milling process, and also protect the clean environment of the insulating workshop.

Besides enclosed shield of the spacer milling machine is made of 2 mm thick steel plate and toughened glass and electric interlock, when the machine start, can effectively stop all kinds of unsafe splash damage and personal, improve the safety.

Main technical parameter for the spacer milling machine

Processing range:

Block length: 25 ~ 300 mm

Block width: 25 ~ 60 mm

Pad thickness processing range: the maximum 350 mm

Saw head speed: 3000 r/min.

Saw head movement speed :2 ~ 5 m/min

Arc to speed: 9000 ~ 24000 n/min;

Slot knife speed: 9000 ~ 24000 n/min;

Machining precision block length: quipment processing all kinds of precision block length shall meet the + / - 0.2 mm

Machining accuracy of groove of block: block equipment processing all types of precision dovetail, dove tail, straight groove depth should meet the + / - 0.2 mm, equipment shall ensure that the processing of longitudinal and lateral two block material direction compaction, the compaction, machining process block material should be vertical and mesa not tilt, to ensure that the processing of various types of rabbet center with pad material overlap, deviation should

be + / - 0.15 mm.

Spacer milling machine body steel members for aging treatment, main transmission parts should undertake the corresponding heat treatment.

Motor installed capacity: about 16 kw (not including the dust collector motor)

Spacer milling machine weight: 3.5 tons;

Pneumatic system pressure and flow rate: 0.6 MPa and 0.2 m3 / min

Machine Video

5A Solution Provider

We are 5A Class Transformer Home with a full solution for Transformer Industry

A1, We are a real manufacturer with complete in-house facilities

A2, We have a professional R&D Center, having collaboration with well-know Shandong University

A3, We have Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

A4, We are better cost-efficient and convenient supplier equipped with international brand components like Simens, Schneider, etc

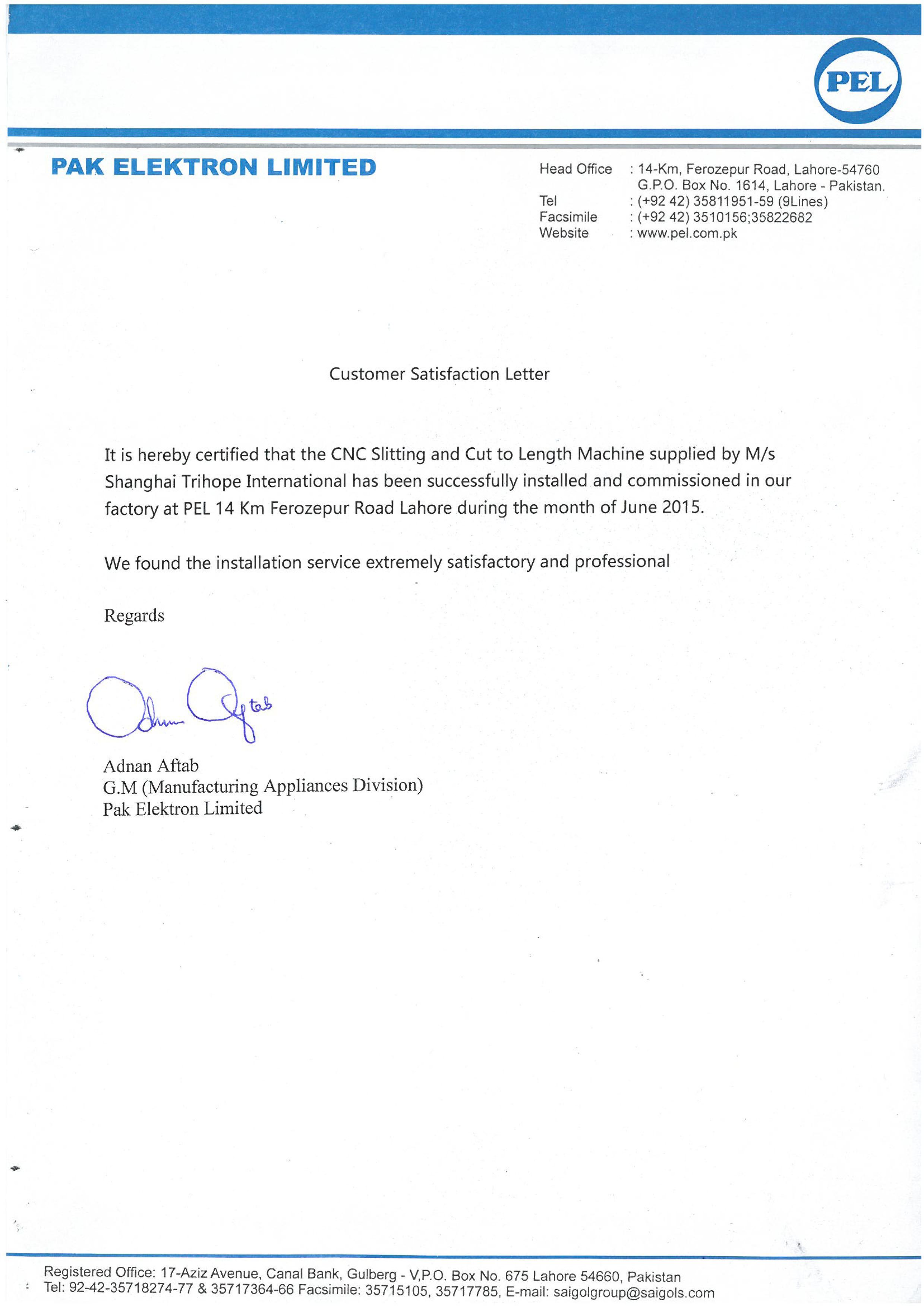

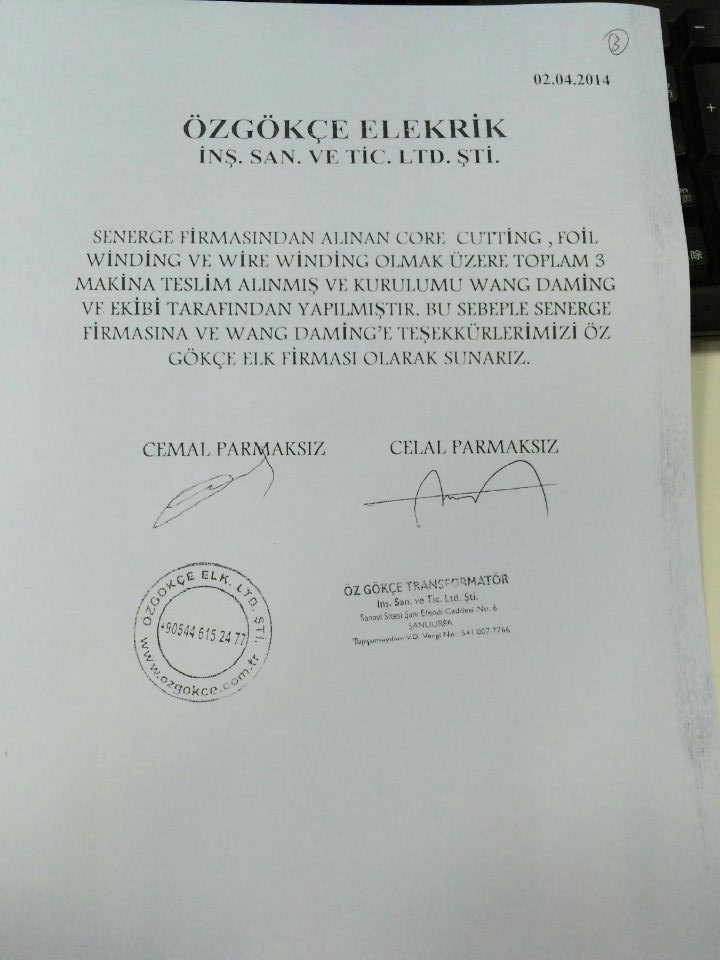

A5, We are a reliable business partner, served for ABB, TBEA, PEL, ALFANAR, etc in the past 17 years

FAQ

Q1: How could we choose the right model foil winding machine?

A: Please give us your details coil size, material size, special requirements, Our engineer will finalize which model suitable for you.

Q2: Can you provide the turn-key service of supplying complete machinery and equipment for a new transformer factory ?

A: Yes, we have rich experience for establish a new transformer factory. And had successfully helped Pakistan and Bangladesh customers to build a transformer factory.

Q3: Can u provide the After-sales installation and commissioning service in our site?

Yes, we have the professional team for after-sales service. We will provide installation manual and video when machine delivery, If you need, we can also delegated engineers to visit your site for installation and commission. We promise we will provide 24 hours of online feedback when you need any help.

+862164567713

+862164567713 trihope@aliyun.com

trihope@aliyun.com